A conduit bender is a specialized tool designed to bend conduit pipes used to house electrical wiring or other systems. This tool is essential for creating precise angles and shapes in conduits to fit around obstacles or to conform to specific installation requirements. Conduit benders are indispensable in both residential and commercial electrical installations, as well as in HVAC and plumbing applications.

Basic Components

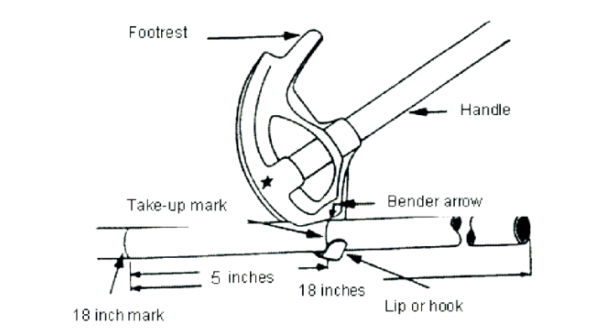

Understanding the anatomy of a conduit bender is crucial for effective use. Here’s a detailed breakdown of its main components:

- Bender Head: This is the part of the tool where the conduit is placed and bent. It often includes degree markings to help achieve precise bends. The head is usually made of heavy-duty materials to withstand the force applied during bending.

- Handle: Attached to the bender head, the handle is used to apply force to the conduit. It provides leverage, making it easier to bend the conduit with less effort.

- Foot Plate: The footplate stabilizes the bender and provides a steady base. It ensures that the conduit remains in place during bending, preventing unwanted movement or shifting.

- Degree Indicators: These markings on the bender head allow you to measure and achieve specific angles. They are crucial for making accurate bends, especially when electrical installations require precise angles.

How a Conduit Bender Works

Step-by-Step Process

The process of using a conduit bender involves several steps:

- Positioning the Conduit: Place the conduit into the bender head, ensuring it is aligned with the degree markings. The conduit should be positioned correctly to achieve the desired bend angle.

- Applying Force: Use the handle to apply force to the conduit. As you push down on the handle, the conduit will begin to bend. Apply a steady and even pressure to avoid any kinks or distortions.

- Checking Alignment: After bending, check the conduit against the degree indicators to ensure the bend is accurate. Make any necessary adjustments by re-bending if needed.

Tips for Accurate Bending

- Pre-Measure: Before bending, measure the length of the conduit and mark the location where the bend will occur. This helps in achieving the correct angle and ensures that the conduit will fit properly in its intended location.

- Use Proper Technique: Apply force smoothly and evenly to prevent uneven bends. It’s important to maintain control over the bending process to avoid damaging the conduit.

Types of Conduit Benders

Manual Conduit Benders

Manual conduit benders are simple, hand-operated tools designed for smaller projects. They come in various sizes and are suitable for bending conduits like EMT (Electrical Metallic Tubing) and PVC. Manual benders are easy to use and transport, making them ideal for on-site work.

Hydraulic Conduit Benders

Hydraulic benders utilize hydraulic pressure to bend conduit pipes. They are designed for more extensive and complex jobs where manual bending might be impractical. Hydraulic benders offer greater precision and require less physical effort, making them suitable for high-volume bending tasks.

Electric Conduit Benders

Electric conduit benders are powered by electricity and are used for high-volume and repetitive bending tasks. They are often found in industrial settings and can handle larger diameters of conduit. Electric benders are efficient and capable of making multiple bends quickly.

Advantages of Using a Conduit Bender

Precision and Accuracy

A conduit bender ensures that bends are made with precision, which is crucial for fitting conduit pipes accurately in various installations. Accurate bending helps in achieving a professional finish and prevents the need for additional adjustments or rework.

Time Efficiency

Using a conduit bender speeds up the bending process compared to manual methods. This efficiency is particularly beneficial for professionals working on large projects or tight deadlines, as it reduces the overall time required for conduit installation.

Cost-Effectiveness

Investing in a high-quality conduit bender can lead to cost savings in the long run. By reducing the need for costly adjustments and minimizing errors, a conduit bender helps in maintaining project budgets and ensuring high-quality installations.

Practical Uses of Conduit Benders

Electrical Installations

In electrical installations, conduit benders are used to shape conduit pipes to route electrical cables safely and effectively. Properly bent conduit helps protect wires from physical damage and ensures a clean, organized installation.

HVAC Systems

For HVAC systems, conduit benders are used to shape ductwork and conduit pipes that are part of the ventilation and air conditioning systems. Accurate bending ensures that the ductwork fits properly and operates efficiently.

Plumbing

In plumbing applications, conduit benders can be used to shape pipe conduits, which helps in protecting plumbing lines and ensuring they are routed correctly through walls and other structures.

Conclusion

Mastering the use of a conduit bender is essential for achieving professional results in electrical, HVAC, and plumbing installations. Understanding its components, how it works, the different types available, and the advantages it offers can greatly enhance your efficiency and accuracy in various projects. For additional information, you may explore external resources on conduit bender maintenance and advanced bending techniques. For more related tools and equipment, visit our internal resources on electrical and plumbing tools.